Richard Ha writes:

We had a short employee meeting at lunchtime yesterday, to look back a bit and see where we are today, and also to catch everybody up on what’s going on.

We had a similar meeting three years ago, when we had a crisis. I told our workers that C. Brewer was selling all of its sugar lands, including the land under our banana farm, which we were leasing. We had two choices: 1) Do nothing, in which case it would be likely the land would be subdivided for home sites and we would probably have to quit farming, or 2) Buy the land.

We didn’t know how we were going to pay for the land but we decided to try. We put in an offer to Willie Tallett of C. Brewer. Our offer was accepted and we had four years to come up with the balloon payment.

That was then. Now, three years later, the land’s value has multiplied by nearly eight times. We’ve been able to sell off some of it and pay down the land note, and we’re still left with 590-something acres.

What a difference this has made. When we leased, we could not do any real, long-term planning. Now we say that we will be farming for another hundred years. And we’re serious.

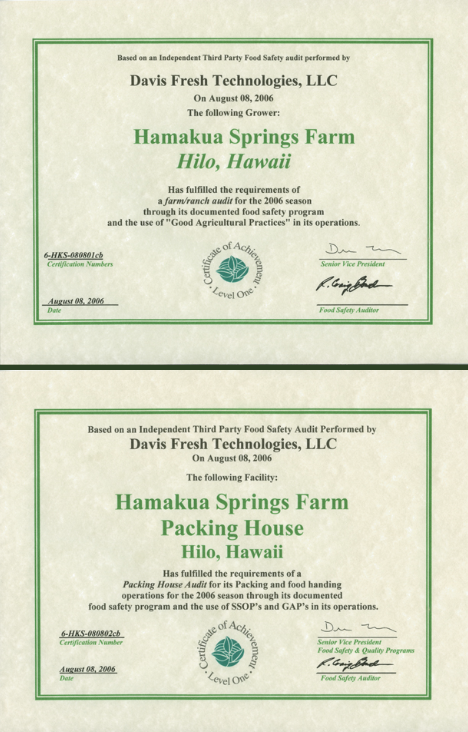

In the last few years we have diversified into hydroponic vegetable production, and we’re comfortable that we’ve figured that out.

At our meeting yesterday, I informed everyone that we just reroofed our old sugar company warehouse, which we will start using soon as a farm stand. When we’re satisfied that we’ve figured out what we’re doing, we will move to the “Gears”—our new property across the highway, where the big gear stands—and build a farm stand and snack bar there. We hope it will be a venue for community events and festivals.

At our meeting yesterday, I informed everyone that we just reroofed our old sugar company warehouse, which we will start using soon as a farm stand. When we’re satisfied that we’ve figured out what we’re doing, we will move to the “Gears”—our new property across the highway, where the big gear stands—and build a farm stand and snack bar there. We hope it will be a venue for community events and festivals.

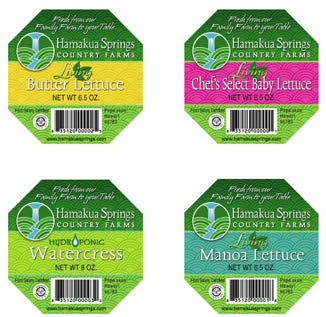

I mentioned that we are in the middle of a tomato recipe contest with the Hawai‘i Community College culinary program; we are helping our neighbors—the residents of Andrade Camp—upgrade their private water system to county standard; Chef Alan Wong will visit us soon. We were just recently on the semi-finals and finals of the Top Chef show. I asked if everyone saw our new company newsletter, which we are starting to put in each paycheck envelope. The Hamakua Springs brand is growing by leaps and bounds. Things are going well. Let’s eat.

The company bought lunch, and the office personnel and management served. I even made the salad.

The food was from Hilo Lunch Shop:

Real crispy fried chicken

Ono tempura

Shoyu Pork

Corned beef hash patties

Macaroni potato salad

Hamakua Springs tomato, lettuce, cucumber salad

Everyone loved the Hamakua Springs salad. I told them it was a recipe that June and I learned from Chef Alan Wong.

Recipe:

5-1/2 ounce container of Hamakua Springs Chef Select Salad. Break lettuce into bite sized pieces.

3 medium-sized beef clamshell Hamakua Springs tomatoes, cubed.

2/3 of a Hamakua Springs Japanese cucumber, cubed.

Place cubed tomatoes and cucumbers in bowl. Marinate with Hawaiian salt and black pepper for 15 minutes.

Add:

1/2 tablespoon minced garlic

1/2 tablespoon grey poupon mustard

1/2 tablespoon minced shallots

1/2 tablespoon chopped parsley

Toss.

Make a mixture of 1 part balsamic vinegar to 3 parts extra virgin olive oil. Shake well before use.

Place lettuce in a bowl. Add tomato, cucumber, garlic, mustard, shallot and parsley. Add oil to coat lettuce leaves, toss and serve.

At the end of the day, every worker took home a container of Chef Select lettuce and tomatoes.