Mahalo to Senator Inouye for having the foresight to fund Pacific Basin Agricultural Research Center (PBARC). This might be the game changer for food and energy security for Hawai‘i.

I wrote before that PBARC has been working on a “zero waste” program for the Hamakua Coast.

It’s an impactful and multifaceted program that ultimately ends up supporting both food security and energy security for Hawai‘i. Food security involves farmers farming, and if farmers make money, farmers will farm.

I support this program because utilizing waste products helps farmers make money.

Here I’m writing here about the biofuel (energy) component, which has support from the Department of Defense. One of the fundamentals of making biofuel involves acquiring appropriately priced feedstock. In this model, the feedstock comes from farm waste that is now thrown away. Or it comes from a process such as crop rotation, which enhances primary farming operations.

In the Hamakua Zero Waste Program’s demonstration model, the farm waste will be papaya. Papaya farmers sell 65 percent of what they deliver to the processer, and 35 percent is thrown away. The other product is sweet sorghum, which is used in rotation with a primary crop such as sweet potato.

A very significant part of this program is the use of oil-producing microbes. BioTork LLC specializes in breeding microorganisms that make oil.

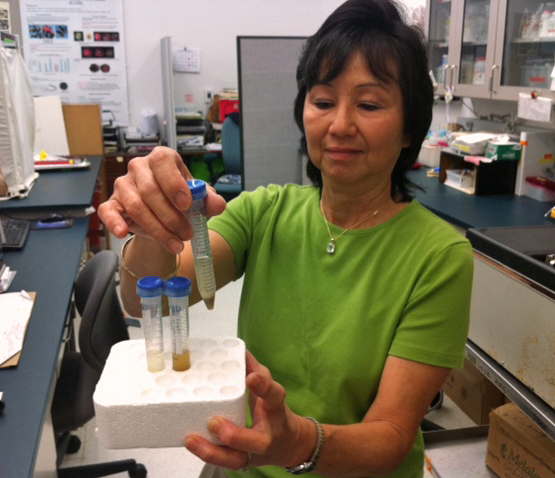

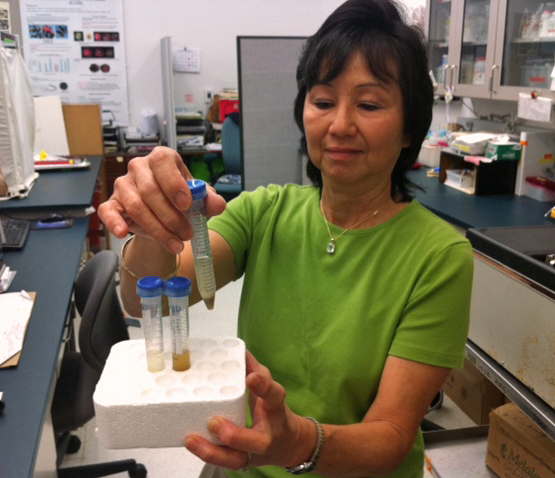

Evolved algae, from BioTork LLC, having just arrived at PBARC in the mail. This is Kate Nishijima, a PBARC researcher.

Evolved algae, from BioTork LLC, having just arrived at PBARC in the mail. This is Kate Nishijima, a PBARC researcher.

Eudes de Crecy, the CEO of BioTork, states:

A variety of different microorganisms—such as heterotrophic, fungi and bacteria—are capable of converting sugars and other organic compounds into triglycerides oils suitable for conversion to advanced drop-in fuels like green diesel, gasoline and jet fuel. Since these oil-producing microorganisms are heterotrophic, they can be grown inside large fermentors or bioreactors in any climate 24/7 and do not require significant amounts of water for growth. Moreover, oil-producing heterotrophs can produce significantly more triglycerides than phototrophic microorganisms—up to 70% of the dry weight. To date, few enterprises use oil-producing microorganisms like to produce biofuel because the carbon sources necessary for robust growth are more expensive (e.g., glucose, fructose) than the resulting biofuel.

However, BioTork has used experimental evolution to produce proprietary oil-producing microorganisms that are capable of growing on low cost streams of organic material. Indeed, we have already adapted oil-producing microorganisms to grow on low value by-products and even noxious wastes that are derived from agricultural or industrial processes.

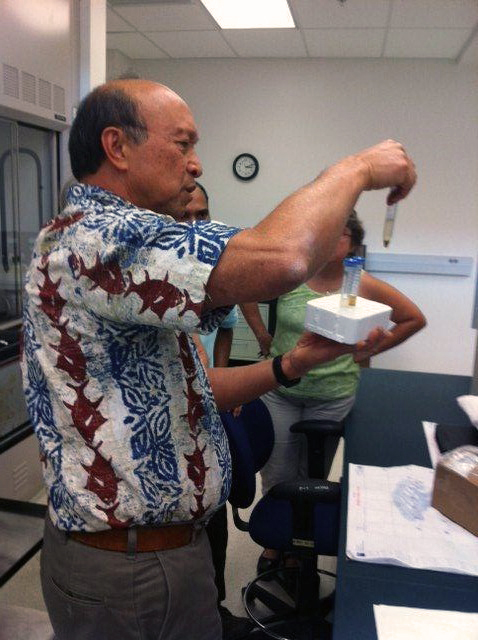

Transferring algae to growing media

Transferring algae to growing media

Hawai‘i-grown papaya was sent to BioTork prior to Christmas 2010, and first generation, oil-producing strains that grow on papaya puree and sweet sorghum juice have already been developed and sent for testing in PBARC’s labs. In addition, preliminary results for the development of an oil-producing microbe that can grow on the less accessible carbon sources in sweet sorghum bagasse looks promising.

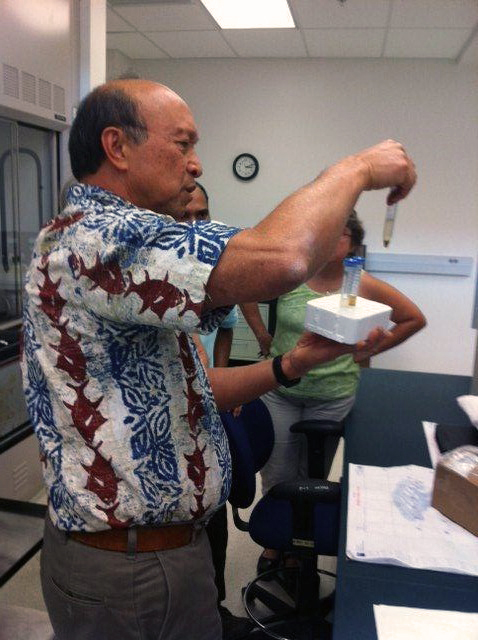

Dennis Gonsalves, PBARC Director, examining a vial of specialized, oil-producing algae

Dennis Gonsalves, PBARC Director, examining a vial of specialized, oil-producing algae

The demonstration project is designed to show whether this will or won’t work within 12 months in a cost effective manner in real world conditions. As a farmer, I believe that if this works cost effectively, it can work on a sustainable basis because it will help farmers make money. And as we all know, if the farmers make money, the farmers will farm.

Rivertop Solutions, LLC, whose CEO is David Rus and whose president and chief media officer is Amy Fernandez, is an important partner of the Hamakua Zero Waste project. Rivertop Solutions works alongside communities and organizations to assist with the planning, systems design, and implementation of economically and socially viable development programs based on maximizing the potential of indigenous resources. The company is moving its headquarters from Reston Virginia to Hilo in the summer of 2011.

Together with PBARC’s other programs that support and enhance farming operations, we can build a resilient food security system for Hawai‘i.